What Makes a Food Cartoning Machine Reliable?

2023-10-14

Food packaging plays a crucial role in preserving the quality, safety, and freshness of our meals. It not only acts as a protective shield but also serves as a canvas for branding and conveying important information to consumers. Behind every flawlessly sealed package lies the work of advanced technology, particularly food cartoning machines. In this blog post, we will delve into the fascinating world of food packaging, explore the benefits it brings, and unravel the mysteries of modern food cartoning machines.

The Importance of Food Packaging: Food packaging is vital for various reasons. Firstly, it safeguards the product from external factors such as air, moisture, light, and microorganisms that can compromise its quality and pose health risks. It also extends the shelf life of perishable items and reduces food waste by preventing spoilage. Secondly, packaging acts as a medium for informative labeling, highlighting ingredients, nutritional facts, and allergen warnings, enabling consumers to make informed choices. Additionally, it protects against tampering, ensuring that the contents remain intact until opened, enhancing trust and security in the food supply chain.

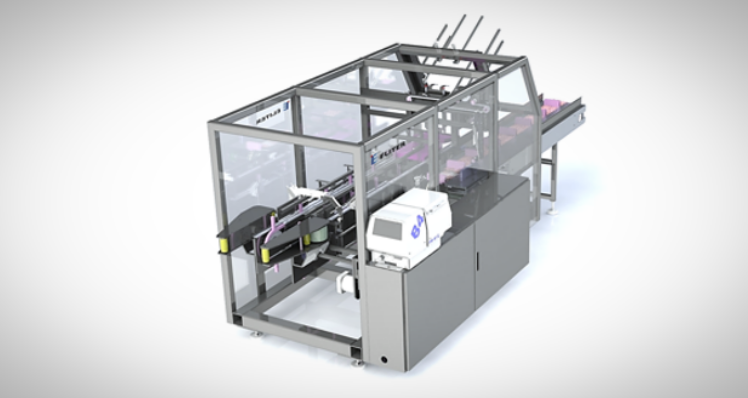

GRAN SONATA FOOD CARTONER BY ELITER PACKAGING

Packaging for food comes in many forms, including cans, bottles, cartons, pouches, trays, and more. Each type has its own purpose and benefits. For instance, cans boast excellent shelf stability and are ideal for long-term storage of goods, while pouches provide lightweight convenience, making them suitable for on-the-go snacks. Cartons, however, offer a perfect blend of functionality and eco-friendliness and are widely used for various food products like milk, juice, cereals, and ready-to-eat meals.

The Concerns with Food Packaging

Food packaging plays a crucial role in preserving the quality and safety of products, ensuring their freshness, and providing important information to consumers. However, there are also concerns associated with food packaging that need to be addressed and mitigated. In this blog, we will discuss some of these concerns and explore potential solutions.

1. Environmental Impact

One major concern with food packaging is its environmental impact. With the increasing amount of packaging waste generated worldwide, including plastic, paper, and metal containers, it is essential to adopt more sustainable packaging materials and methods. For example, single-use plastic packaging contributes significantly to pollution and takes years to decompose. Shifting towards biodegradable or compostable alternatives can help alleviate this issue.

2. Chemical Migration

Another concern is chemical migration from packaging materials into the food itself. Different types of packaging, such as plastics, may contain harmful chemicals like phthalates, bisphenols, and heavy metals. When in contact with food, these substances can transfer and pose health risks. Stricter regulations on packaging materials and increased testing of potential chemical migrations are necessary to protect consumer health.

3. Food Waste and Shelf Life

Packaging also plays a role in reducing food waste by extending product shelf life. Proper packaging techniques can help preserve freshness, prevent spoilage, and minimize losses along the supply chain. However, excessive packaging can lead to overuse of resources and contribute to unnecessary waste. Balancing the use of appropriate packaging materials and optimizing packaging design can have a positive impact on reducing both food and packaging waste.

4. Allergen Contamination

The presence of allergens in food poses a significant risk to allergic individuals. Cross-contamination during packaging processes is a common concern, as trace amounts of allergens in one product can accidentally contaminate other non-allergenic goods. Manufacturers must implement strict protocols and enforce proper cleaning practices to mitigate the risk of allergen contamination and clearly label products to inform consumers about potential allergens present.

While food packaging is essential for ensuring the safety, quality, and convenience of our food supply, it also comes with certain concerns. If you are looking for a european quality food cartoning machines, you can contact ELITER Packaging Machinery who is a manufacturer and global supplier of high quality cartoner.

Addressing these concerns requires a collaborative effort from governments, manufacturers, and consumers. Stricter regulations, increased research and development of sustainable packaging materials, proper labeling, and education on responsible consumption practices are key to mitigating the negative impact of food packaging. By prioritizing environmental sustainability, consumer health, and food waste reduction, we can create a better future for both our planet and our nourishment.

What are the food safety concerns with a cartoning machine for food application?

Food safety is a paramount concern for both consumers and manufacturers in the food industry. In particular, when it comes to packaging food products efficiently and effectively, cartoning machines play a crucial role. Such like the KLIKLOK BEC Cartoner of Syntegon is a best-in-class food cartoning machinne. However, it is essential to address potential food safety concerns that may arise during the use of these machines.

SYNTEGON KLIKLOK BEC CARTONER

1. Equipment Design and Material Selection First and foremost, selecting the right cartoning machine designed specifically for food applications is crucial. Look for machines made from food-grade materials such as stainless steel. These materials are resistant to corrosion, easy to clean, and non-toxic, minimizing the chances of cross-contamination or chemical reactions with the packaged food.

2. Hygiene and Sanitization Protocols Maintaining proper hygiene and adhering to strict sanitization protocols are vital for preventing microbial contamination. Regular cleaning and sanitizing of the cartoning machine, including all its components and contact surfaces, should be carried out to eliminate any harmful bacteria or allergens. Additionally, implementing a routine maintenance schedule will help identify and rectify any potential malfunctions that could compromise food safety.

3. Packaging Materials and Inspection Ensure that the packaging materials used in the cartoning process are suitable for food contact. These materials must meet regulatory standards and be free from toxic substances that can migrate into the food. Performing regular inspections of the packaging materials and verifying their compliance with food safety regulations will help mitigate risks.

4. Quality Control Measures Implementing quality control measures at various stages of the cartoning process is crucial to uphold food safety. This includes monitoring and controlling factors such as temperature, humidity, and air quality. Moreover, integrating advanced technology like vision systems to detect foreign particles or contaminants can help minimize the chance of contaminated products reaching consumers.

5. Staff Training and Education Well-trained operators who understand the importance of food safety are an integral part of ensuring a safe cartoning process. Regular training and education sessions should be conducted to familiarize employees with proper hygiene practices, equipment handling techniques, and the detection of any abnormalities during the packaging process. Encouraging a culture of responsibility among staff members will contribute to maintaining food safety standards.

Regulations that a Food Cartoning Machine Must Comply with

Food cartoning machines play a crucial role in the packaging process of various food products. These machines are responsible for efficiently and safely packing food items into cartons, ensuring their protection until they reach consumers. In order to ensure the quality, safety, and compliance of these machines, they must adhere to specific regulations outlined by the Chinese government. Here, we will discuss some important regulations that food cartoning machines must comply with in China.

-

Food Safety Law: The Food Safety Law of the People’s Republic of China sets out general guidelines for food safety management, including requirements for machinery used in the production and packaging of food products. Food cartoning machines need to meet the hygiene and safety standards stipulated under this law.

-

Technical Standards: China has developed technical standards specifically for food cartoning machines. These standards address various aspects of machine operation, sanitary design, material selection, product handling, and labeling. Manufacturers and operators must comply with these technical standards to ensure safe and efficient packaging processes.

-

Good Manufacturing Practices (GMP): Food cartoning machines are typically used in food processing facilities that follow Good Manufacturing Practices. GMP guidelines lay out the necessary procedures and controls to ensure the integrity of food products throughout the manufacturing process. Compliance with GMP guidelines helps maintain hygienic conditions, prevents cross-contamination, and ensures the safety of packaged food.

-

Product-Specific Regulations: Different types of food products may have specific regulations regarding their packaging. For instance, dairy products, meat, or seafood may require specialized packaging considerations due to their perishable nature. Food cartoning machines need to comply with relevant regulations related to the handling and packaging requirements of specific food products.

-

Equipment Certification: It is essential for food cartoning machines to obtain relevant certifications to prove their compliance with regulatory standards. Chinese authorities require the issuance of certificates, such as the China Compulsory Certificate (CCC), to ensure that the machine meets safety and quality standards.

-

Environmental Regulations: Apart from ensuring food safety, manufacturers must also comply with environmental regulations concerning waste management, noise pollution, energy consumption, and emissions during the operation of food cartoning machines. Compliance with these regulations helps reduce the environmental impact associated with packaging processes.

-

Labeling and Traceability: Food cartoning machines also have an important role in ensuring accurate labeling and traceability of packaged products. Compliance with labeling regulations is crucial for providing consumers with essential information about ingredients, allergens, nutritional values, and expiration dates.

Compliance with these regulations not only ensures the safety and quality of food products but also protects consumers’ health and well-being. It is essential for manufacturers, operators, and other stakeholders involved in the production and packaging process to stay updated with the latest regulatory requirements and implement them effectively.