New biotechnological processes to transform waste and by-products from pineapple, orange and rice into precursors for biodegradable packaging materials and ingredients for cosmetics

2024-01-08

The Itene technology center has developed biotechnological processes for the valorization of agri-food waste and by-products (orange, pineapple and rice husk) to obtain organic acids, which can be used as additives in the food and cosmetics industry and as monomers in the production of biodegradable plastics for the packaging sector.

These findings reaffirm the potential of agri-food by-products from the Valencian Community for obtaining high-value organic acids, validating their applicability in such relevant sectors as packaging and cosmetics.

These investigations have been achieved within the framework of the Essential 2023 project, funded by the Department of Innovation, Industry, Commerce and Tourism and the Smart Specialization Strategy of the Valencian Community S3-CV.

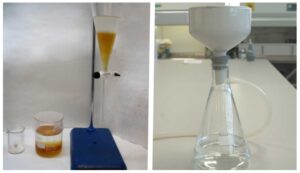

Specifically, the potential of various agri-food by-products for the generation of organic acids of industrial relevance has been evaluated. Specifically, pineapple skin, rice husk and orange peels were chosen due to their rich nutrient content, favoring the growth of fermentative bacteria and promoting innovation in biotechnological processes in the context of the circular economy.

Thus, within the framework of the Essential project, advanced processes have been established for the valorization of agri-food by-products with the purpose of generating high quality organic acids, including lactic acid and succinic acid. These acids not only find application in the packaging sector, but are also relevant in the cosmetics industry. Specifically, lactic acid and succinic acid serve as raw materials for the production of polylactic acid (PLA) and poly(butylene-succinate) (PBS), respectively.

In this sense, the person responsible for the project at Itene, Enrique Cubas, has detailed that “these materials are emerging as essential in the packaging industry due to their biodegradable and compostable nature. Furthermore, its demand is rising in the field of “green cosmetics”, thanks to its beneficial properties that include exfoliating, antioxidant, antimicrobial and moisturizing action, consolidating itself as sustainable ingredients of great value.”

Of the by-products examined, pineapple skin demonstrated exceptional performance, with lactic acid obtained close to 80%. On the other hand, rice husk stood out by achieving an approximate yield of 90% in the production of succinic acid.

The implementation of these processes in the industrial sector provides a series of notable strategic advantages. A significant improvement in the management and disposal of biowaste stands out, which translates into a direct reduction in associated costs. Furthermore, a decrease in expenses is observed in the manufacture of biopolymers by adopting hydrolysates of byproducts instead of conventional techniques.

This adaptation leads to the creation of sustainable and adaptable industrial systems, oriented towards the production of compounds and biopolymers with high demand in the market. This evolution also promotes the creation of innovative value chains, encouraging intersectoral collaborations. In addition, the transition towards economic practices based on circularity and sustainability is reinforced, actively promoting ecological alternatives and progressively replacing petroleum materials with more environmentally friendly options. This holistic approach not only minimizes the ecological impact on industrial operations, but also establishes a clear path towards achieving the objectives proposed by the European circular economy strategy, setting a vital precedent for the manufacture of biopolymers from waste resources. .

Objectives of the Waste Law

The biotechnological advances made by Itene are aligned with its research to generate resources and raw materials from waste through biotechnology. This initiative’s main objective is to valorize agricultural waste and by-products to reduce the environmental impact of these waste. In addition, it seeks to comply with the goals established in the Law on Waste and Contaminated Soils for a Circular Economy for a Circular Economy. This law promotes the separation of waste and establishes a goal of reducing the weight of waste generated since 2010, aiming for a decrease of 13% by 2025 and 15% by 2030.