Materials cycle: reuse, the key to conserving resources

2022-12-25

While our last articles have focused on the concept of circularity, circular strategies and indicators to measure it, today we want to focus on what we understand by “materials cycle”. One of the key objectives of circularity is to “circulate products and materials (at their highest value)”. But in order to circulate materials or products, we first have to understand what a materials cycle is.

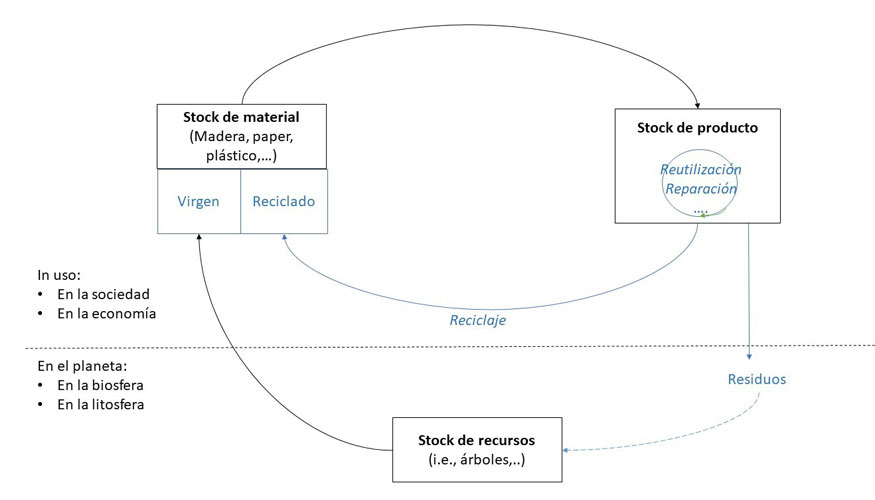

Rankin (2014) defined the materials cycle as one that integrates three components that are interrelated:

- First of all, the stocks or the stock of resources, which are the resources present on the planet (i.e. trees, oil, etc.);

- secondly, the material stock, which is made up of the materials obtained from resources (i.e. wood from trees, plastic from oil);

- and thirdly, the stock of products that are the goods or products that are manufactured from the materials and are used by society.

However, this Rankin approach can be further improved (see Figure 1) by distinguishing, firstly, two types of materials (virgin, which comes directly from nature, and recycled, which results from the technosphere); and secondly, by adding circular strategies (such as reuse, repair, recycle). Taking into account this cycle of materials, represented in Figure 1, the challenge is to ensure an adequate management of the three stocks or stocks mentioned to close the cycle of materials and, thus, reduce the demand for virgin material and the generation of waste.

Figure 1: Diagram of a materials cycle, adapted from Rankin’s (2014). The blue rows and words have been added from the original diagram.

The cycle of materials in food distribution

When applying this theoretical framework to the food distribution sector, it is necessary to analyze four main types of boxes:

- single-use cardboard boxes,

- single-use wooden boxes,

- single-use plastic boxes

- and reusable plastic boxes.

In the case of cardboard and wooden boxes, the key strategy is to optimize the management of the resource stock (trees), since it is a renewable resource; and in the case of cardboard boxes, in addition, quality losses and material degradation must be taken into account, since the fibers can only be recycled 3 times (Delgado-Aquilar et al., 2015).However, in the case of reusable plastic boxes, the key strategy is to maximize the product stock, that is, to improve the product life cycles through its recovery, repair and reuse, since the resource is not renewable (oil).

In addition, plastic boxes can also be recycled; in closed or open circuit. We speak of closed circuit when the recovered material has the same function as the virgin and is used for the same purposes; while we speak of open circuit when the recovered material is used to manufacture other products with properties inferior to those of the original.

In the case of plastic boxes, current scientific articles usually consider an open circuit recycling, with a certain loss of quality (70% according to Albrecht et al., 2013). However, these containers can be recycled in a closed circuit with 100% material recovery, as IFCO claims in its Cradle to Cradle certification. This helps to maximize the stocks of recycled material and to decrease the use of virgin material and close the cycle even more.

However, in addition to the management of these three types of stocks, to achieve circularity two key principles must be taken into account: (i) to narrow the cycle and (ii) for as long as possible (Sazdovski et al., 2021); which means that all strategies that improve the “product stock” component should be prioritized. Hence, as we already commented in a previous article (in which we made reference to the report by Potting et al. (2018)), all those strategies such as reuse, repair, reconditioning and remanufacturing are preferable to recycling and recovery.

In this regard, Erwijk et al. (2020) stated that “waste recycling cannot create a perfect circle because the increasing demand for materials exceeds the available waste from previous consumption, materials are lost or degraded during processing, and the energy needed for processing increases as collection rates grow.”In addition, they conclude that greater circularity by increasing recycling and recovery does not imply a direct reduction in greenhouse gas emissions, due to the energy consumption used in recycling.

In summary, companies and, in general, supply chains must have a holistic perspective of the materials/products they use/sell when redesigning their system towards circularity. It is essential to always keep in mind that strategies to maintain product stock are crucial, and that the materials cycle must be as tight and long as possible.

Reference:

Albrecht, S., Brandstetter, P., Beck, T. et al. An analysis of the extended life cycle of packaging systems for the transport of fruits and vegetables in Europe. Int J Life cycle assessment 18, 1549-1567 (2013). https://doi.org/10.1007/s11367-013-0590-4

Delgado-Aguilar, M., Tarrés, Q., Pèlach, M. À., Mutjé, P., Fullana-I-Palmer, P., 2015. Are cellulose nanofibers a solution for a more circular economy of paper products? Environ. Sci. Technol. 49, 12206–12213. https://doi.org/10.1021/acs.est.5b02676 .

van Ewijk S., Stegemann, J. A. and Ekins P., 2021. Limited climate benefits of global pulp and paper recycling. Sustainability of nature volume 4, pages 180-187. https://doi.org/10.1038/s41893-020-00624-z

Potting Joseph and Hanemaaijer Aldert (eds.), et al. (2018). What we want to know and can measure. Reference system and evaluation for monitoring the progress of the circular economy in the Netherlands. PBL Environmental Assessment Agency of the Netherlands, The Hague.

Rankin, W. J. and Tsukihashi, F., 2014. Environmental aspects and the future of process metallurgy; in Treatise on Process Metallurgy: Industrial Processes.

Sazdovski I., Bala A. and Fullana-i-Palmer (2021) Linking the LCA literature with the value creation of the circular economy: A review on beverage packaging. Environmental Science Total 771 (2021) 145322. https://doi.org/10.1016/j.scitotenv.2021.145322

ÉLITER Packaging Machinery (2022): Cardboard Sleeve and Plastic Replacement – a more Sustainable Approach to Environmentally Friendly Packaging https://www.eliter-packaging.com/