High performance packaging for chocolate

2022-12-27

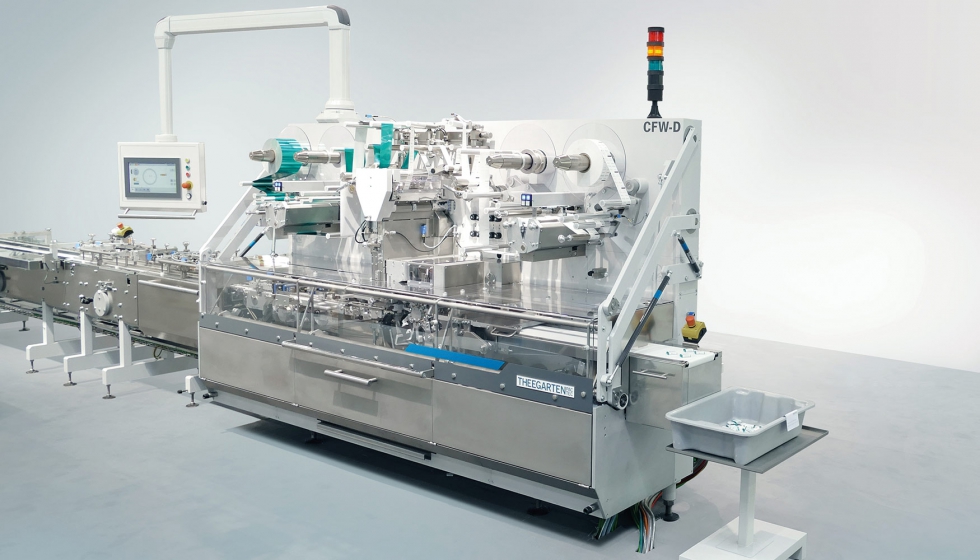

Theegarten-Pactec is a manufacturer of high-performance wrapping machines for small-sized confectionery. The Dresden company is continuously expanding its range and working on the development of its machinery. At the ProSweets trade fair in Cologne (hall 10.1, stand G020/H029), the specialist presents its most recent developments for the packaging of chocolate items: the CFW-D high-performance wrapping machine for chocolate products in a folded wrapper, which sets a new record with a maximum throughput of up to 1,400 products per minute.

Maximum performance through double-track construction

The new CFW-D from Theegarten-Pactec offers confectionery manufacturers a wrapping machine that wraps filled or coated chocolate items and wafers with a maximum throughput of up to 1400 products per minute in folded wrapping, with or without a seal. At ProSweets, a machine demonstrates the packaging of small chocolate tablets in a folded sealed envelope type.

The high performance of the CFW-D is made possible by the double-track construction of the machine. The tolerances of the products are compensated by clamping jaws with suspension on the packing head. They also ensure a particularly careful packaging process, a decisive aspect especially for coated confectionery products. Thanks to the sensory recording of the supply performance, the machine speed can be optimally controlled depending on the products introduced and the dynamic pressure on the products can be minimized.

The CFW-D for chocolate products in a folded wrapper sets a new record with a maximum throughput of up to 1400 products per minute.

Images: Theegarten-Pactec.

Machine states always in sight

The machines of Theegarten-Pactec are controlled via a touch panel with an intuitive user interface as standard, which ensures easy operation of the wrapping machine. Important information such as the total efficiency of the equipment and the cleaning and maintenance cycles can be displayed clearly and easily on the monitor. Even unqualified operators can effectively operate the line thanks to the intuitive presentation and instructions. The issuance of self-diagnostics of the equipment favors the resolution of problems and the increase of performance of the machine. A direct access to the user manual and the spare parts catalog allows the operator personnel to solve possible faults quickly and, thus, avoid unnecessary downtime. Also, the machine control includes the display of the maintenance and cleaning cycles, as well as an active message indicating the required service and maintenance intervals.

“The continuous development of our machines in terms of transparency of the production process, automatic self-diagnosis and guidance for troubleshooting using an intuitive touch panel and graphical representations is a priority issue for us. We make our machines even more efficient and intuitive,” explains manager Markus Rustler. “In the future, the user interface will be integrated into mobile devices, so that machine data can be consulted and managed from anywhere in the world.”

In addition to an improved analysis of production data, such as total equipment efficiency and capacity utilization, Theegarten-Pactec is currently working on condition Monitoring of its machines. Other issues are the self-regulation of machines, for example, in case of incorrect positioning of products in the packaging process.