Food Manufacturing Companies Can Expect more Compact High-Speed Cartoner

2023-08-11

Boxes of cereal, frozen pizza loaded in plastic tray and wrapped by sleeve, a big carton of breakfast cookies, etc… packaging in the food industry is usually big and of large volume, while basically a majority of them are packed in carton boxes. Do you know that cartoning for large cartons and boxes has been a long-lasting problem for both food manufacturing companies and packaging machine manufacturers?

Cartoning Machines can be Large for Food Application

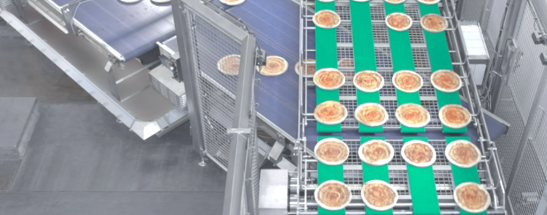

Cartoning machine is a typical form of packaging machine to pack miscellaneous food products into carton boxes, paper carton, cartonboard boxes, etc. The machine is usually designed with a specific pitch distance to fit a range of box sizes. All along the machine’s operation there are various positions and stations for carton erecting, loading, closing and for discharge.

When it comes to food products, ready meals, chocolates, pizza, cereal, muesli, avena, and so forth, which are often very big, cartons that carry them can be large. Correspondingly, a cartoning machine must have a longer pitch length to fit such big cartons. A result is that, the cartoning machine’s footprint will be expanded significantly, then larger footprint, as well as the more expensive cost.

This is typical when it comes to continuous motion cartoner, which is an advanced packaging machine for box, and with a complex system of loaders to realize intensive frequency of insertions.

According to Colin P. Ford of Graphic Packaging International LLC.,

“Barrel cam loaders are a container loading system of a carton packaging machine which consists of a conveyor and transfer flight. There is a series of pivotable cradle lugs installed on the transfer flight that follow a synchronous motion with the carton boxes erected by the cartoning machine and the packages of materials loaded on the bucket conveyor. The system continuously loading sideways products into the carton boxes during the operation.”

Though such a system on a continuous motion and high-speed cartoner is a commonly recognized solution, it is not friendly to food manufacturing companies with limited space and limited budget. As we can see that barrel cam loader system is such a complex mechanism that can drive the cartoning machine’s cost sky-high, and can make a machine very big and heavy due to the longer pitch length.

Packaging Machinery Manufacturers are Researching new Solutions

Packaging machine manufacturers in the field of food packaging automation solutions have been researching and developing a new form of loading system to make continuous motion cartoning machine affordable and smaller in size.

Triangle Package Machinery Co., for example. has developed a special cartoning machine for large articles such cereal bags and chocolate bars. The machine is assembled with a loader and vertical indexer. The former is built on a pair of horizontally extending driving belts to support cartons from one end to another end. A conveyor reaches to the carton’s open end and leads bags of cereal into the erected carton directly. All the construction is mounted vertically thus there is a smaller footprint.

ÉLITER Packaging Machinery, a packaging machine manufacturer located in Wenzhou, China, seeks a different outlet. The company has developed a smart and servo-driven loading system to replace the barrel cam loaders, thanks to which the continuous cartoner can be compact while with speed of high level guaranteed.

Food companies can now expect affordable high-speed cartoner

Innovations and creativity by packaging machine manufacturers worldwide have made the cartoning as compact and of fast speed as possible. Kliklok Woodman LLC., a company of Syntegon Group, is also paying importance to develop a new model of cartoner, which is upgraded BEC horizontal end-load cartoner. Food companies now have more and more choices to find out the cartoning right for their needs.