Twinseal Carton Sealer Is A Star At Prostar

2022-12-06

Prostar Packaging, Inc. was founded in 2006 by James Cash and Clinton Van Zyverden. With an excess of 100,000 square feet of space in Pottstown, PA, Prostar offers first rate contract packing, warehousing, and logistics services to their customers. The contract packaging/fulfillment side of the business requires ultimate flexibility in the firm’s packaging capabilities, providing low cost results, and the need to follow customer supplied packaging specifications without any exceptions.

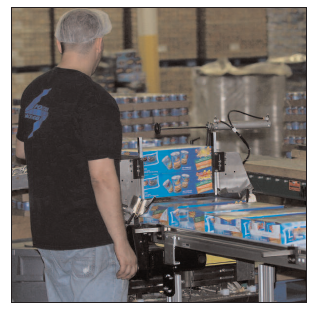

One of Prostar’s customers recently asked for a very fast response to the need to carton canned goods and due to the fast start up mode required the company found the need to start the project by using hand-held glue guns. “We knew that in order to be competitive and maintain this business, we needed to reduce our labor costs,” stated James Cash, Prostar President and CEO. “Randy Stauffer of Shrink Packaging Systems has helped us with past projects and recommended that Prostar take a closer look at the ECONOSEAL Twinseal carton sealing machine. Given Econocorp’s assurance that the Twinseal could do the job, we made the decision to purchase the equipment,” added Cash.

Based on the need to use more than one operator to achieve the required line speeds, ECONOCORP also recommended that the option of an ECONOSEAL choke fed belt conveyor should be integrated with the Twinseal. This format eliminates the need for any operator attendance at the carton sealing machine.

An operator(s) simply place loaded cartons with inner flaps closed onto the continuously moving conveyor belt at random and the remainder of the operation is automatic. Guide rails keep the inner flaps closed as cartons travel to the sealer. As one carton pushes another into the sealer and a carton reaches the gluing station, the machine cycle is automatically initiated. Both ends of the sleeve style carton receive glue and the carton is then elevated into a vertical compression station. Elevating the carton reduces machine floor space and helps to keep the finished carton very square and attractive. Completed cartons are then removed from the machine back to a convenient working height for the next operation via the delivery chute accessory.

Prostar also commented, “The Econocorp team provided outstanding support during our acceptance testing. When we requested a modification at acceptance testing, Econocorp fabricated parts so we could ship the machine and run it the next day. Prostar installed the equipment ourselves and it has performed flawlessly with minimal support from maintenance personnel. As a customer, we could not ask for any better response and results.”

The ECONOSEAL choke fed Twinseal operates at 1,440 cartons per hour (24 cartons per minute) and has enabled Prostar to reduce their labor costs on this project by 16%. The machine will provide a payback period of less than one year.

Find more:https://www.econocorp.com/