BLM cartoner complements BCW3 primary packaging machine for West African broth cube manufacturer

2023-10-14

Universal Investment & Industries in Ghana, West Africa, wanted to invest in Theegarten-Pactec ‘s BCW3 primary packaging machine , but also needed a cartoner that could match its high performance. With their in-house developed BLM, the German packaging machine specialists had the perfect solution and were able to use it for the first time under real conditions in the industry.

Ghanaian company Universal Investment & Industries, based in Accra, has been successfully established in the services and packaging sector for years. It packages confectionery products, such as chocolate and biscuits, as well as powdered milk and bouillon cubes for cooking. For years there has been a good collaboration with the German company Theegarten-Pactec, specialized in packaging machines for small confectionery, food and non-food products.

At its Ghana plant, for example, Universal Inv. & Ind. uses a Theegarten-Pactec BCW3 specially designed for the primary packaging of pressed bouillon cubes. This proven, high-performance packaging machine processes up to 1,400 stock cubes per minute in side folding, making it currently one of the fastest stock cube packaging machines in the world.

Ghana-based contract manufacturer Universal Investment & Industries needed a cartoner to complement

Theegarten-Pactec’s BCW3 primary packaging machine and live up to its high performance. The ideal solution: the self-developed BLM.

For maximum efficiency: two machines from the same supplier and with the same performance

In order to carry out the secondary packaging of the broth cubes in the same company and in a particularly efficient way, at Universal Inv. & Ind. needed to purchase a corresponding machine. In light of their previous experience, it was logical to ask the German packaging machine specialists, who presented them with the BLM cartoner as the ideal solution and installed it at the end of 2022.

One of the main advantages that made Universal Inv. & Ind. chose the BLM was that, in this way, its packaging process came from a single supplier. The BLM has the same operating concept as the BCW3, ensuring optimal communication and control between lines and significantly reducing interface problems such as product jams. An advantage that translates into a particularly efficient process. Furthermore, because they have the same intuitive concept, operational errors are minimized. If, despite this, faults or errors occur between the primary packaging machine and the secondary packaging machine that they cannot solve alone, the employees of Universal Inv. & Ind. can contact Theegarten-Pactec directly for diagnosis and quick resolution of the fault.

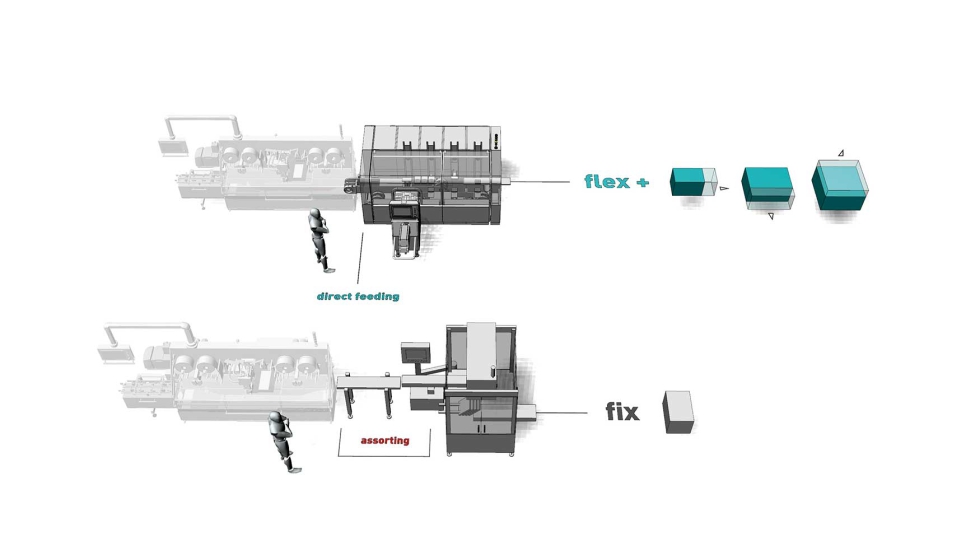

No interface issues: Direct feeding and perfect coordination of the primary packaging machine

and the BLM offered Universal Investment & Industries a highly efficient packaging process.

Industrial test of the first self-developed cartoner

The BLM is the first cartoning machine from Theegarten-Pactec. After five years of development and rigorous testing, Universal Inv. & Ind. is the first company to use the BLM in the industry. Christian Pötsch, Head of Sales for Africa at Theegarten-Pactec, says: “The BLM has achieved excellent test results. However, we cannot simulate 100% all the eventualities that may occur, which is why it always generates great expectations for us to install a machine for the first time in a customer’s plant and start it up in real conditions. An industrial trial that was a resounding success.The BLM is a modular system and processes different product sizes, case dimensions and product formations in various performance ranges. It fits products with primary packaging, such as chocolate bars in folded wrappers or tubular bags, chewing gum in folded wrappers, pressed powdered milk bars and non-food items such as stacked dishwasher tablets. At Universal Inv. & Ind., BLM is used for secondary packaging of bouillon cubes. Currently, the BCW3 dispenses up to 1,400 broth cubes per minute and the BLM packages them in cardboard boxes with the same output. The secret: coupling the BLM by direct feeding, which eliminates the need to reorder products.

The BLM convinces with its efficiency, easy handling and compact design

Christian Pötsch is very satisfied with the result: “The BLM is perfectly suited for connection to the high-performance BCW3 machine. From experience we know that many companies find it not easy to find a suitable cartoner that matches the high performance of the packaging machine. This limitation often means that the packaging process cannot be carried out at full capacity, leading to a decrease in efficiency. BLM allows small food and non-food products to be packaged at high speed.”

Another aspect that also convinced Universal Investment & Industries was the compactness of the BLM. Thanks to its design, the cartoner helps save additional tapes and interfaces in the company and requires much less space in production than conventional top-loading machines. In addition, its low height provides the operator with an optimal view of the entire packaging line. Its operation is also very simple: the BLM is managed entirely from the front. In this way, walking distances are short and easy, so employees save time, and the machine is perfectly accessible for operation, maintenance and cleaning. Thanks to its modular design, the machine can be adapted to the possibly difficult structural conditions of the production hall if necessary. A transparent machine cover allows additional visual control to be easily carried out.

A flexible and therefore cost-effective solution

Another feature of the high-performance cartoner that especially appealed to Universal Investment & Industries is the flexibility of the BLM. Regarding the arrangement of the product in the boxes, with a single machine, single-row, multi-row and multi-layer containers, among others, can be formed. In addition, the BLM’s expansion options also contribute to flexibility: for example, an additional coding device can be integrated for the expiration date or batch number, a continuous format change without tools or a network connection for remote diagnosis.

Thanks to the modular design of the BLM, a precise configuration could be made for the specific needs of Universal Investment & Industries. In any case, the installation of the BLM in West Africa has been a resounding success: “Our customer’s reaction shows that he is extremely satisfied: he has already received a second production line composed of the BCW3 and the BLM,” adds Christian Pötsch .